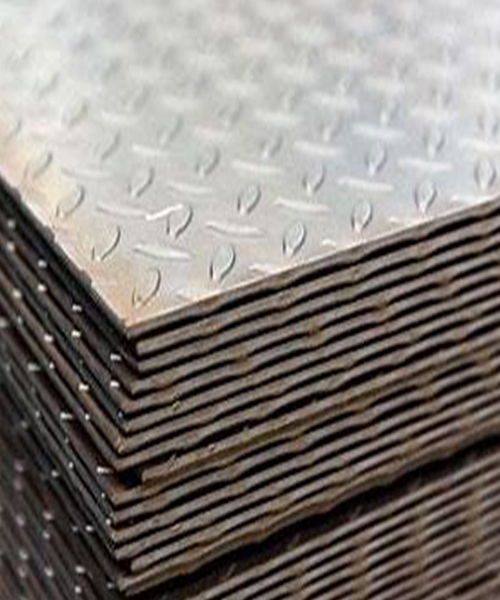

Stainless Steel Plates Manufacturers

Contact : +919353077501

Stainless steel plates are versatile and widely used materials in various industries due to their strength, durability, and resistance to corrosion. Available in different grades, sizes, and finishes, stainless steel plates are essential in applications ranging from construction to food processing. This article will explore the benefits, applications, and key considerations when selecting stainless steel plates.

Benefits of Stainless Steel Plates

-

Corrosion Resistance: One of the primary reasons stainless steel plates are favored is their exceptional resistance to corrosion. Stainless steel contains chromium, which forms a thin layer of oxide on the surface, protecting it from rust and corrosion even in harsh environments. This makes stainless steel plates ideal for applications where exposure to moisture, chemicals, or extreme temperatures is common.

-

Strength and Durability: Stainless steel plates are known for their high tensile strength, making them suitable for heavy-duty applications. They can withstand significant pressure and weight, ensuring longevity in structures and machinery. This durability reduces the need for frequent replacements, offering long-term cost savings.

-

Hygiene and Easy Maintenance: The smooth surface of stainless steel plates makes them easy to clean and maintain, a critical factor in industries like food processing, pharmaceuticals, and healthcare. The material is non-porous, meaning it does not harbor bacteria or contaminants, ensuring a hygienic environment.

-

Aesthetic Appeal: Stainless steel plates have a modern and sleek appearance, making them a popular choice for architectural and interior design applications. Their reflective surface can enhance the visual appeal of buildings, kitchens, and other spaces.

Applications of Stainless Steel Plates

-

Construction and Infrastructure: Stainless steel plates are extensively used in construction for making structural components like beams, columns, and supports. Their strength, corrosion resistance, and low maintenance requirements make them ideal for bridges, buildings, and other infrastructure projects.

-

Automotive and Transportation: In the automotive industry, stainless steel plates are used to manufacture parts like exhaust systems, chassis, and body panels. Their ability to withstand high temperatures and resist corrosion ensures vehicle longevity and safety.

-

Food Processing and Hospitality: The food industry relies on stainless steel plates for manufacturing equipment such as tanks, conveyors, and work surfaces. The material’s hygiene properties and resistance to food acids and chemicals make it the best choice for this sector.

-

Chemical and Petrochemical Industry: Stainless steel plates are used in the chemical industry to fabricate tanks, reactors, and pipelines. Their resistance to a wide range of chemicals ensures safe and efficient operations in corrosive environments.

-

Marine Applications: Given their excellent resistance to saltwater and marine environments, stainless steel plates are used in shipbuilding, offshore platforms, and coastal structures. They ensure the longevity and safety of these structures.

Key Considerations When Choosing Stainless Steel Plates

-

Grade Selection: Stainless steel plates come in various grades, each suited for specific applications. Common grades include 304, 316, and 430. For example, 304 is ideal for general purposes, while 316 offers better corrosion resistance for marine and chemical applications.

-

Thickness and Size: The thickness of stainless steel plates varies, and the choice depends on the intended use. Thicker plates are suitable for heavy-duty applications, while thinner plates may be used for lighter, decorative purposes.

-

Finish: Stainless steel plates are available in different finishes, such as brushed, polished, and matte. The finish affects the plate's appearance and its suitability for certain environments. For instance, a polished finish is often used in kitchens and laboratories for its ease of cleaning.

Conclusion

Stainless steel plates are a vital component in numerous industries due to their strength, durability, and resistance to corrosion. Whether for construction, automotive, or food processing, selecting the right grade, thickness, and finish is essential for achieving the desired performance and longevity. By understanding the benefits and applications of stainless steel plates, businesses can make informed decisions that enhance efficiency and reduce costs.